The original idea for this wall cupboard comes from Heiko Rech. He did an online course to build an in german called “Kleines Hängeschränkchen” on his website where he describes how to craft this small wall furniture out of waltnur and maple. I watched that online course since I was interested in building small furniture out of lumber. After watching more videos provided by him sich as building a cupboard and how to do veneering I decided to combine some of the presented techniques and build my version of the wall cupboard. Sounds a bit too much and at the end I even added another detail to the cupboard, but it turned out great and I learned a lot.

Finally for the build of that wall cupboard I have not used walnut or maple lumber at all. I did use some bassworrd lumber pieces to create the kumiko patterns in the front doors. All the parts of the cupboard are done using 18mm thick baltic birch plywood for the carcass and 6mm baltic birch plywood for the back. I did use the techniques in that small cupboard which I wanted to practice before I build a bigger highboard for our living room. The idea was to better try on a small than on a big one, possibly fail and scrap big pieces rather then small.

The measurements of the wall cupboard are 60x40x20cm. The self veneered substrate has a thickness of 18mm. I use american walnur veneer which I ordered from Metz Furniere in Germany. I did not use a professional veneer press. The veneer is pressed onto the substrate but I used an improvides version of a press consisting of two 30mm melamin coated boards. I just used all my clamps to press the veneer on the substrate. The results are perfect. The veneer sits tight on the plywood. The edges I coated with walnut edge veneer of 2mm thickness. To glue the veneer to the substrate I use Titebond T25403 Cold Press Veneer Leim which I distributed onto the substrace using a foam roller.

| Prepared edge veneer | Glued edge veneer |

|---|---|

|

|

After the edge veneed glue dried, I flush the edge with a hand plane.

| Planing the edge veneer |

|---|

|

After the boards are surrounded by the walnut edge veneer I had to prepare the veneer for the boards. Since I have veneer which is 15cm in width but the cupbard has a depth of 20cm, I had to joint 2 pieces of veneer together. I did fix the veneer pieces using painters tape which does not stick to agressive. The tape did

| Joining the veneer sheets |

|---|

|

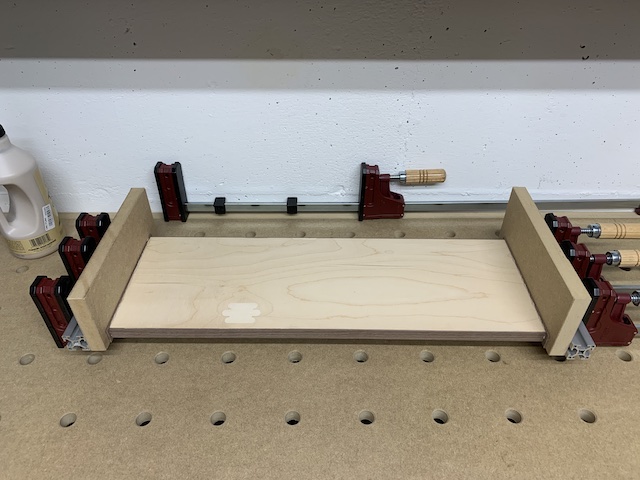

Now the glue has to be added to the substrate. I use a foam roller to do that. The amount of glue you can see on the pictures is enough. While pressing the veneer on the substrate not too much of the glue is squeezed out and if it sqeezes out you can quickly sand that from the edges. I did try to use a spatula to add the glue but I was not convinced with that method. There is too much squeeze out which ends in a real mess.

| Applying glue to the substrate | Glue added |

|---|---|

|

|

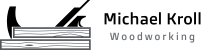

The next step is to add the veneer to the glued substrate and press it in the improvised, but well working, 30mm veneer press.

| Veneer applied | Veneer Press |

|---|---|

|

|

Those steps are now repeated until all pieces are veneered including the back which is done using 6mm plywood.

| The veneered parts for the wall cupboard |

|---|

|

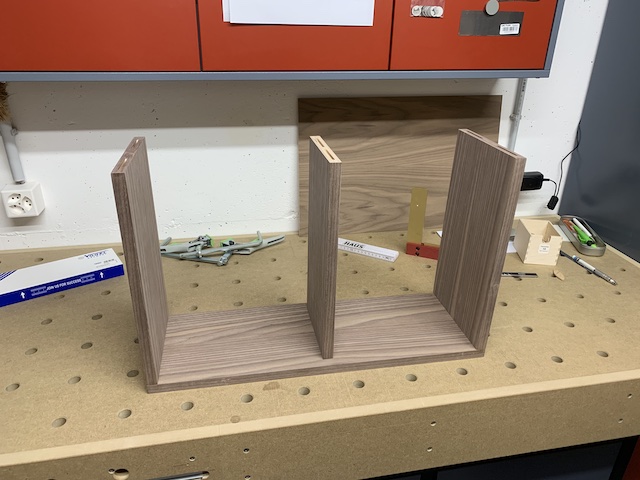

Assembling the cpboard togehter shpuld be achieved using biscuits joints. The shelfs and overlay hinges should be attached holes drilled using a shelf drilling jig. In the following image you can see the biscuit joints already cut and the holes for the shelfs and hinges drilled.

| Biscuit joints cut and holes for shelves and hinges drilled |

|---|

|

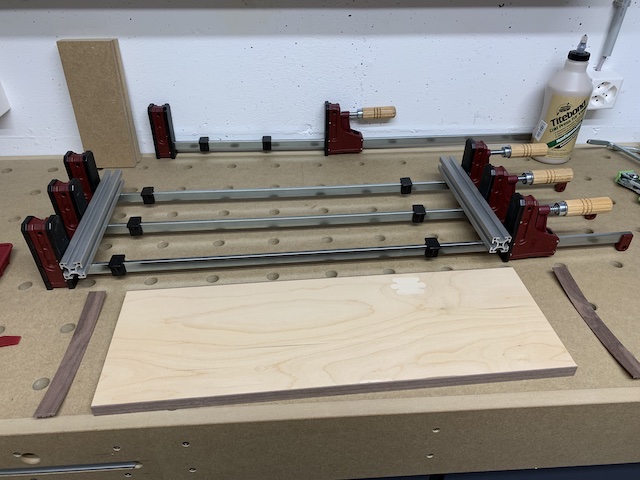

Before I glue the cupboard together I did a dry run if everything fits together as planned.

| Plugged together | Back panel added…. fits. |

|---|---|

|

|

Now it’s time to add finish to the boards excluding the joints where I will add glue. I covered the glue lines with some painters tape. Then I added some oil to the surfaces since at least inside the cupboard it would be difficult to add the oil properly. (Yes, the surfaces were sanded, 120, 180, 240 and vaccumed before adding the oil.)

| Preparation | Oil added to the surfaces |

|---|---|

|

|

I was not in a rush so I let the oil harden some days. After the wait time I glued the carcass together.

| Preparation | Glued together |

|---|---|

|

|

I kept the cupboard a couple of days in the workshop until I mounted it in out living room. Sadly I missed to take photos when I prepared the divider shelfs. I did use 10mm baltic birch plywood which were veneered using the same process as I described before.

| Wall Cupboard without doors |

|---|

|

As you can see in image and read from the caption of the image it is still a cupboard without doors. It was planned to create the doors using the same process as the rest of the cupbaord from baltic birch plywood veneered with walnut veneer and attach them to the corpus using overlay hinges offering very precise means to adjust the position of the door so that I can get the 3mm gaps between doors and corpus. The handles are planned to be attached using system 32 holes.

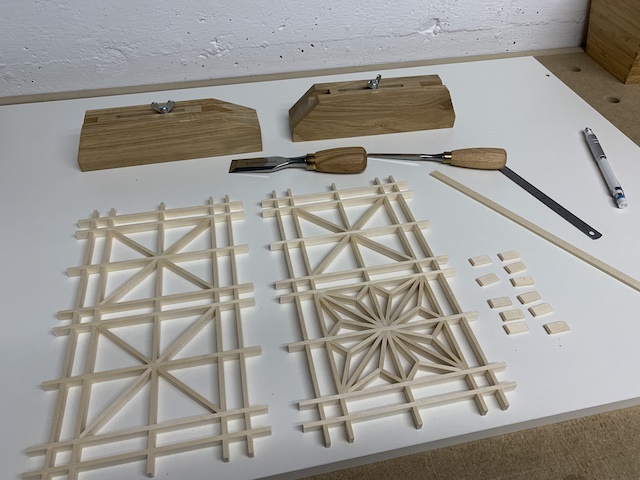

“Sadly” a book from Matt Kenney crossed my plans to create simple doors. The book that I found on the internet is: The Art of Kumiko: Learn to Make Beautiful Panels by Hand

“Sadly” was not meant negative. I had the idea that I need to integrate a Kumiko pattern into the front of my doors. I decided to go with the Asa no ha pattern. I build necessary jigs as described in Matts book, bought basswood and prepared the strips of 8x3.2mm wood to create the patterns. For cutting the pockets into the doors I build a simple but precise router surfacing jig and ordered some jigs from Bau Woodworks to create the small kumiko wood parts using a chisel.

| Jig for the table saw | Kumiko Jigs |

|---|---|

|

|

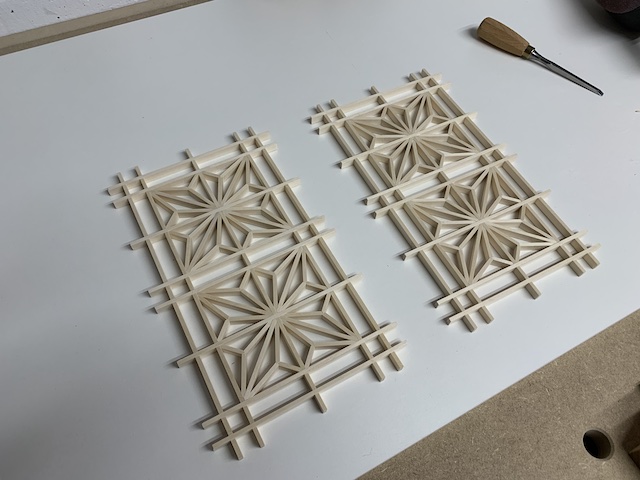

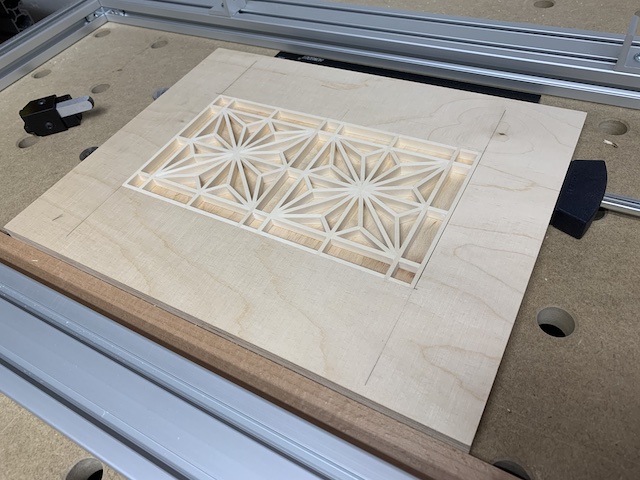

After some trial and error while creating the wood strips, the impression that I must have cut 1000 pieces of bass wood, I have finished to panels of 24x13cm. For my first try creating a Kumiko pattern I was very happy with the result. What I need to improve is to cut the joints in the think stripes by hand since doing that on a tablesaw feels not good and safe.

| Asa no ha Panels for the doors |

|---|

|

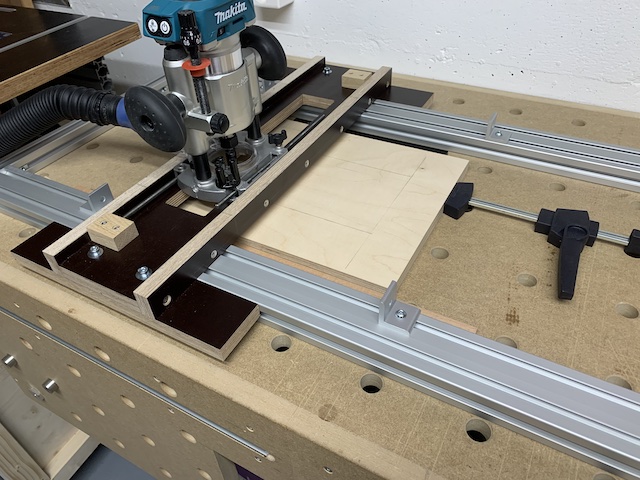

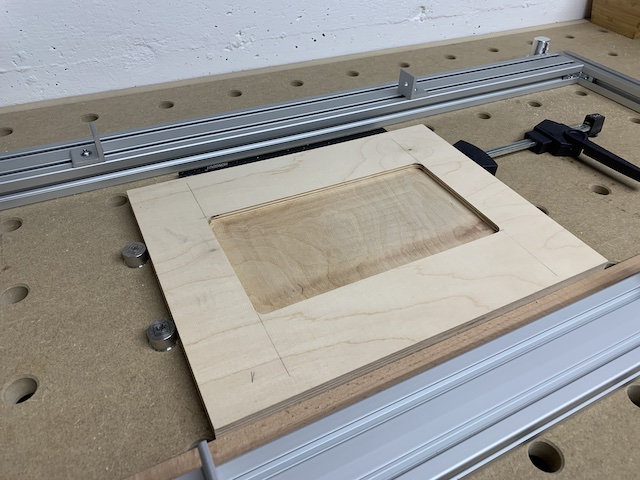

Since the panels are now finished I need suitable pockets to fit these into the doors. I had the idea to create a simple router surfacing jig inspired by some builds available on the web but with stop blocks to get the precise fitting pockets. Using some aluminum bars, some plywood I created a solid and reusable jig to integrate the Kumiko panels precisely into the two doors. It looks like a manually operated CNC.

| Router surfacing jig | Detail view |

|---|---|

|

|

Cutting the pockets into the doors worked great and very precise. It gives you a good feeling when the effort to build a jig pays out and it can be reused. Of course the corners are round and needed to be cut into rectangular shape. You could you a chisel for that but in that case I used a tool from Sautershop to achieve that task. I ordered the so called “Corner Chisel” from Sautershop in Germany.

| Pocket created | Panel fits! |

|---|---|

|

|

To fit doors appereance into the rest of the cupboard the edges and surfaces were veneered with walnut veneer. To the surface of the pocket I glued Shoji paper so that the Kumiko has a clean contrast. I created two of the doors for the cupboard.

| The finished door |

|---|

|

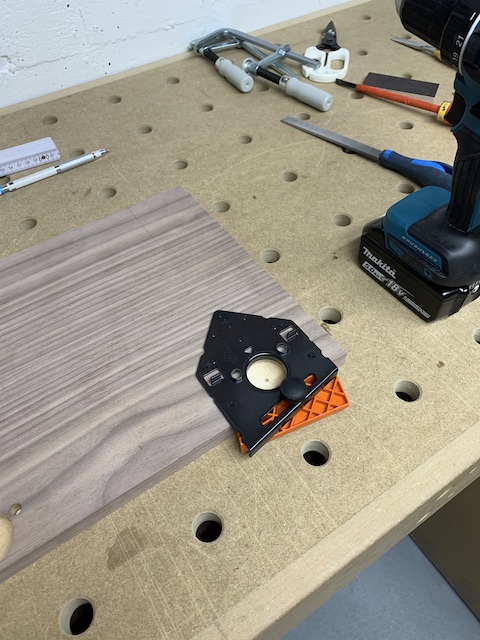

The last step is now to drill the holes for the hinges. Therefore I used drill guides from Kreg and Blum.

| Kreg drill guide | Blum drill guide |

|---|---|

|

|

We are getting closer to the finisheing touches. In the image below you can see the oiled doors, the mounted hinges and the Shoji paper attached to the backsides of the Kimiko panels.

| Doors, hinges, Shoji Paper |

|---|

|

And now the final look at the Wall Cupboard. The handles were created out of massive walnut and basswood. The holes to attach the handles are drilled with 32mm distance to each other so they could be replaces with others in the future if needed. (They were already replaced by black metal ones to fit the handles of the highboard that I build. The description of the highboard build can be found in the next blogpost).

| Wall Cupboard |

|---|

|

Even though you cannot see much from the original plan provided by Heiko Rech I like that small Wall Cupboard very much. I tried and applied lot of techniques and build some jigs and I have to say that there were not much mistakes done during the build. At the end of the build you can tell what could have done better. Of course you will avoind those mistakes but will probably do others. The Cupboard was attached to the wall using a french cleat bar. To avoind that you can look behind the cupboard I added some brush seal as another detail.

The small wall cupboard was created in the timeframe from mid december 2020 until end of january 2021.